Automotive

Precision plasticating solutions for high-quality automotive components requiring consistent melt quality and performance.

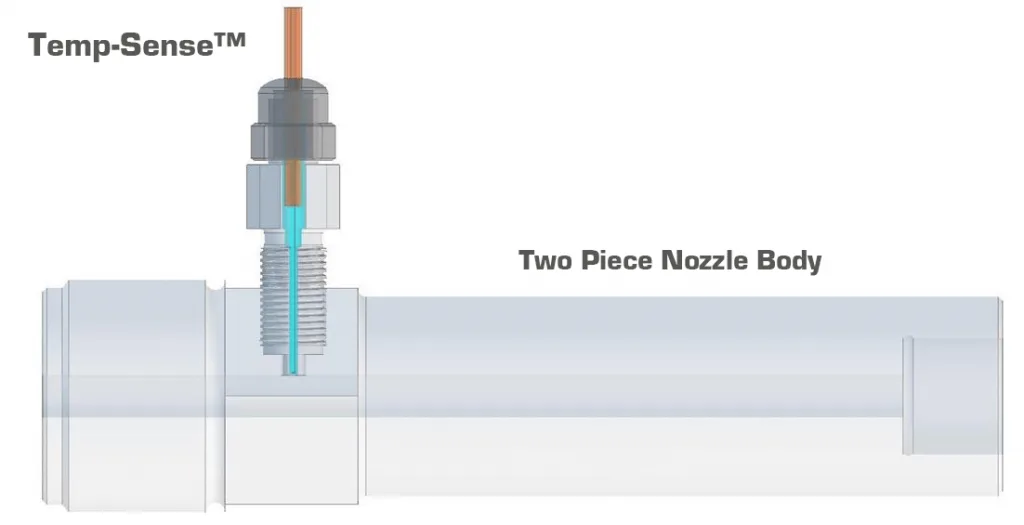

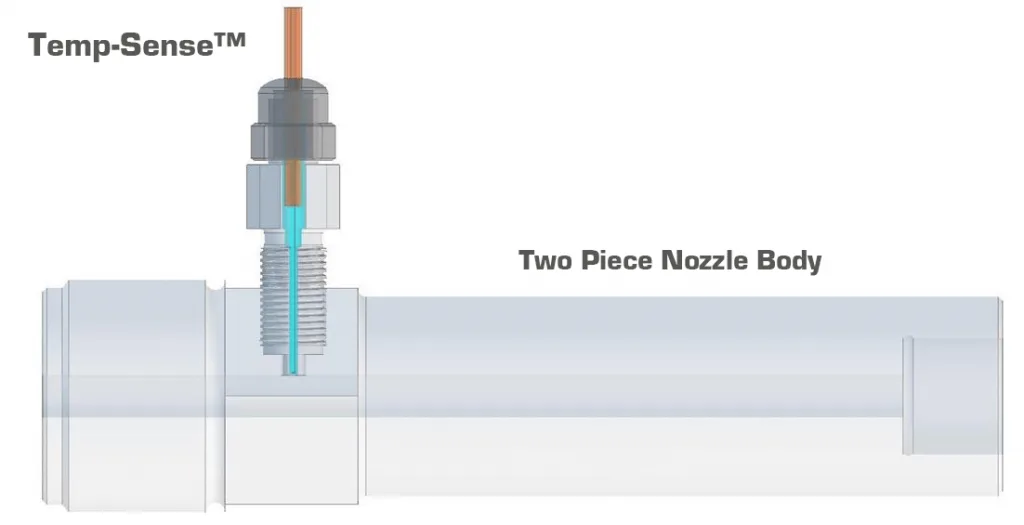

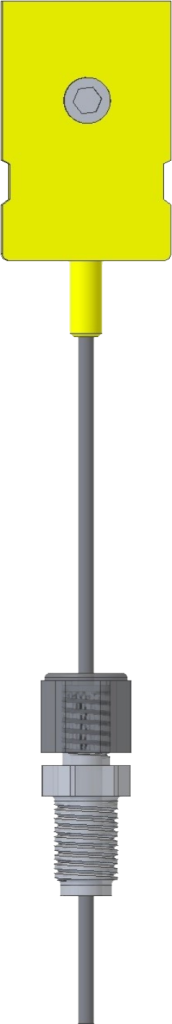

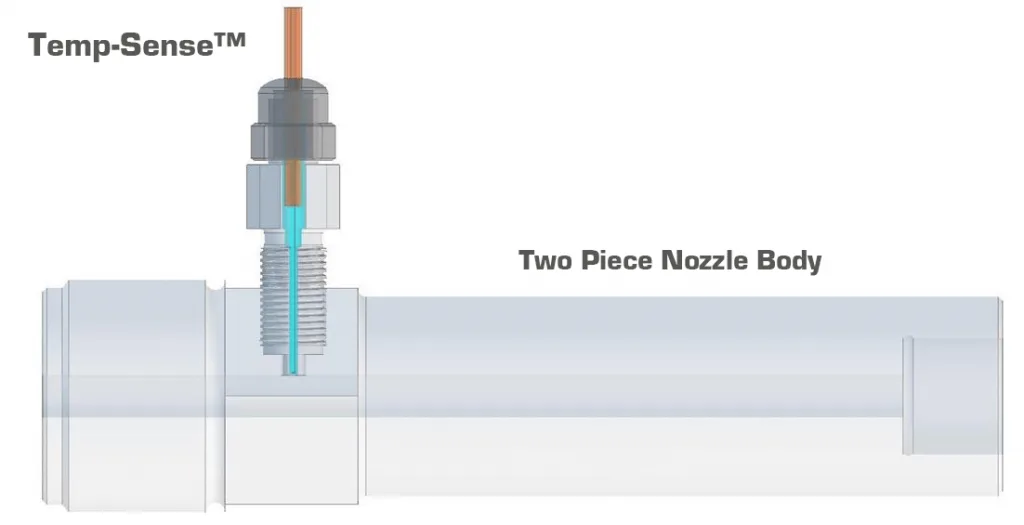

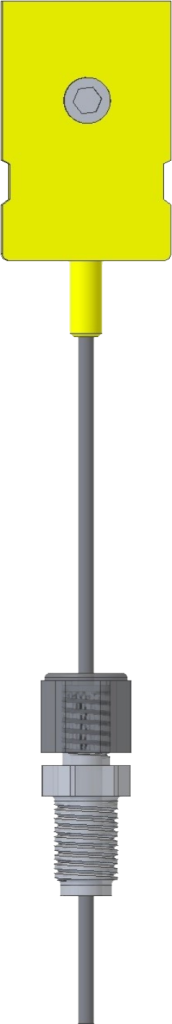

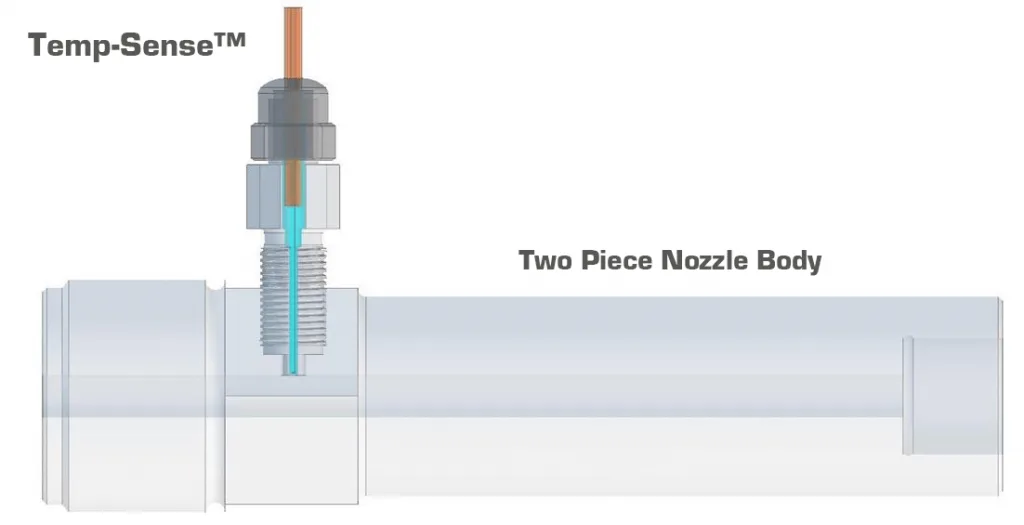

Temp-Sense™ In-Mold Sensor CF25-28

Price Available on Request

Compact flush-mount in-cavity temperature sensor for advanced polymer flow and melt monitoring.

Patented micro-bead technology delivers unmatched accuracy and reliability for your injection molding processes.

Monitor melt pool temperature continuously with direct contact measurement technology providing instant feedback for process optimization.

Built to withstand harsh manufacturing environments with high temperatures, pressures, and corrosive conditions for maximum uptime.

Patented micro-bead sensors deliver precise polymer readings enabling superior quality control and consistent part production.

Flush mount capability and protective armored cables make installation possible in challenging geometries and smaller molds.

Choose from various models including TS-TJC36-2.0, TS DYN-TJ36-3.9, and in-mold sensors to match your specific requirements.

Backed by US Patents #7,585,166 and #6,649,095 ensuring you get innovative technology with proven performance.

Access detailed installation guides and specifications for all Temp-Sense™ In-Mold Sensor CF25-28 models.

Serving diverse sectors with specialized plasticating solutions for enhanced manufacturing performance.

Precision plasticating solutions for high-quality automotive components requiring consistent melt quality and performance.

Advanced plasticating technology ensuring purity and precision for critical medical device manufacturing applications.

Innovative solutions for complex electronic housings and components requiring superior surface finish and dimensional accuracy.

Specialized plasticating systems for 3D printing and additive manufacturing, delivering consistent filament quality and material flow.

Comprehensive plasticating solutions for general plastic processing applications across various manufacturing sectors.

Discover our integrated plasticating systems and monitoring solutions that work seamlessly with Temp-Sense™ In-Mold Sensor CF25-28 technology.

Revolutionary plasticating system with stationary Posi-Melt™ screw providing consistent output-recovery time, inline polymer flow for energy efficiency, and ultra precise shot control with patented mechanical shut-off.

Windows-based system with temperature readings in two second intervals, includes Temp-Sense™ In-Mold Sensor CF25-28 sensor, data acquisition device with USB connector, and proprietary data logger software for continuous monitoring.

Advanced melt-sensing system that knows when good or bad parts are made, measures real time melt temperature and mass displacement, turns any machine into a 5-star quality control manager with powerful microchip processor.

Our technical experts will help you select the perfect Temp-Sense™ In-Mold Sensor CF25-28 configuration for your specific application.

Get expert consultation on implementing Temp-Sense™ In-Mold Sensor CF25-28 technology in your manufacturing process and start improving quality today.

For immediate technical support, call (330) 482-5100 or email us at info@mdplastics.com

For immediate technical support, call (330) 482-5100 or email us at info@mdplastics.com